HealthSCREEN UK

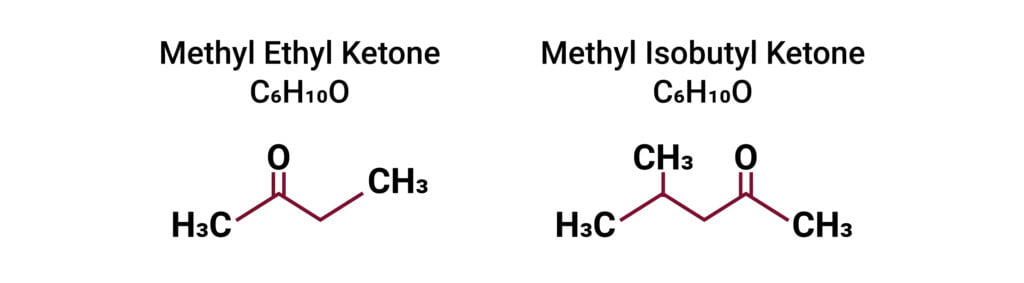

MEK or MIBK

MEK (Methyl Ethyl Ketone) and MIBK (Methyl Isobutyl Ketone) are commonly used solvents in various industries such as surface coatings, adhesives, printing inks, chemical intermediates, and more. While these solvents offer versatile applications, it is crucial to monitor exposure to MEK or MIBK to ensure the safety and well-being of workers.

How We Support You

Our experienced team understands the risks associated with MEK and MIBK and conducts thorough risk assessments tailored to your specific workplace. We take into account factors such as the nature of the work, processes involved, and potential sources of exposure to accurately evaluate the risks associated with these chemicals.

Through our monitoring process, we collect urine samples from employees exposed to MEK or MIBK and use state-of-the-art equipment to measure the exposure levels. We follow industry best practices and guidelines to ensure accurate and reliable results. Our data analysis provides valuable insights into the concentration levels of these chemicals, allowing us to assess the potential risks and take appropriate actions to protect your employees.

Our reports are designed to provide clear and concise information, highlighting the findings of our monitoring activities. We include recommendations for control measures based on the identified exposure levels. These control measures may include engineering controls, such as improved ventilation systems, work process modifications, or the use of personal protective equipment. By implementing these recommendations, you can effectively mitigate exposure risks and create a safer working environment.

Main Benefits:

Monitoring MEK or MIBK exposure provides several benefits, including:

- Identifying areas or processes with elevated solvent concentrations.

- Assessing the effectiveness of control measures in reducing exposure.

- Protecting the health and well-being of employees working with these solvents.

- Complying with regulations and standards related to solvent exposure.

- Preventing symptoms and health issues associated with solvent exposure.

- Providing a benchmark for comparing exposure measurement results.

Ensuring Regulatory Compliance

Compliance with regulations is vital in maintaining a safe working environment and protecting the health of employees. MEK and MIBK are hazardous substances subject to various regulations and guidelines, including the Control of Substances Hazardous to Health (COSHH) Regulations 2002. By utilising our MEK or MIBK Monitoring service, organisations can ensure compliance with these regulations, fulfil their legal obligations, and effectively manage the risks associated with MEK or MIBK exposure.

FAQ:

Inhalation of MEK can cause irritation of the nose and throat, as well as dizziness, headache, nausea, and confusion. Severe exposure may lead to unconsciousness. Skin contact with MEK may cause mild irritation, and ingestion can result in severe lung damage or even death.

Exposure to MIBK can cause headaches, weakness, dizziness, sleepiness, and sleeplessness. Skin contact with MIBK can irritate the eyes, nose, and throat, leading to coughing and wheezing. High levels of MIBK exposure can be fatal and may cause narcosis, leading to loss of consciousness.

Monitoring helps ensure that exposure levels are within safe limits and that control measures are effective. It allows employers to assess the impact of solvents on employees’ health and make improvements to reduce exposure if necessary.

If you are concerned about MEK or MIBK exposure in your workplace or require monitoring services, contact us at Healthscreen. We offer comprehensive monitoring solutions to assess solvent exposure levels and ensure the safety of your employees. Take a proactive step towards a healthier work environment by contacting us today.

Methyl Ethyl Ketone (MEK) Monitoring – The Need to Knows

What is MEK? Methyl Ethyl Ketone, otherwise known as MIBK or butanone is a colourless liquid with an acetone-like odour. It is mostly used in

What is Health Surveillance

Health surveillance is a system of ongoing health checks. These health checks may be required by law for employees who are exposed to noise or

What is Biological Monitoring in Industry?

Learn about what Biological Monitoring can offer your company through this handy article: